Sunday, December 16, 2012

Dec 3-7, 2012: Silver soldering, Chippers and Forklifts

Hours: 50

Hours to date: 509

Sunday, December 2, 2012

Nov. 26 - 30, 2012 : Expo, Flaring, Electical diagnostics

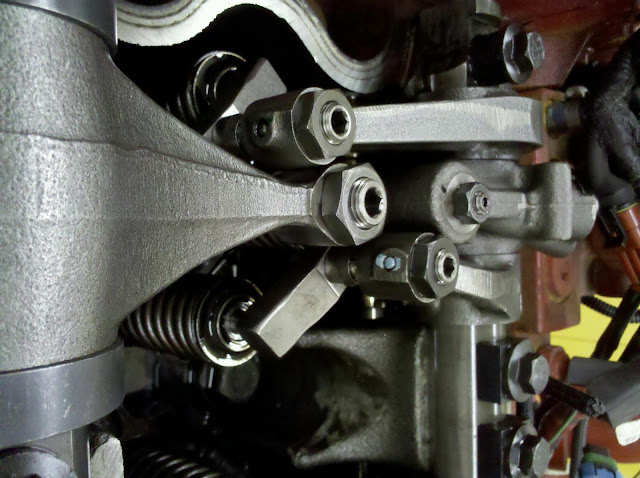

This past week has been definitely something to remember. On Tuesday, I got to go to the Pacific Marine Expo in Seattle. My dad, Sven, also came to join as you can see in one of the photos. It was really eye opening to understand all the new technology in marine diesel. I got to check out some very large engines. It's hard to see in my photo, but it is a flake ice maker for a boat. I got to understand how it works and why the fisherman like flake ice instead of cubes. I also did an assignment with the Cummins ISX. I got to learn more about scanning with a computer. I adjusted the valves and the injector on one of the cylinders. To wrap it up I got to learn how to double flare a brake line. In my photo is one of the lines that I flared.

Hours: 40

Hours to date. 459

Sunday, November 25, 2012

Nov. 18- 25, 2012: backhoes and hydraulic hoses

This past week was thanksgiving. I was able to get some work done before I went on break. I learned more about backhoes, Z60's hydraulic routing and propane regulators. I started with a checkin on a john deere backhoe. Nothin stood out in terms of problems, but it did give me a good refresher on going through them because I hadn't had the chance to check one in awhile. The next was a case 580. This unit needed some parts and small repair, but in the end turned out that I learned how the backhoes joystick system works. It had a bad gas shock that was supposed to keep the joysticks where you wanted. The Z60 had a bad hydraulic hose and when I went to take the cover off and replace it it had more hoses that needed replacing. As you can see in my pictures I also learned about how propane regulators work, backhoe hydraulic routing, bad PCV hose and air intake. Another good week!

Hours: 30

Hours to date: 419

Sunday, November 18, 2012

Nov. 12- 16, 2012: The light board and learning new machines!

Sunday, November 11, 2012

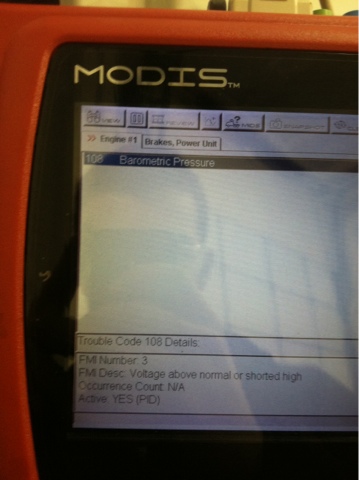

Nov.5-9, 2012: starters, lab scopes and the Modis

Hours: 45

Hours to date: 344